Natural rubber membranes

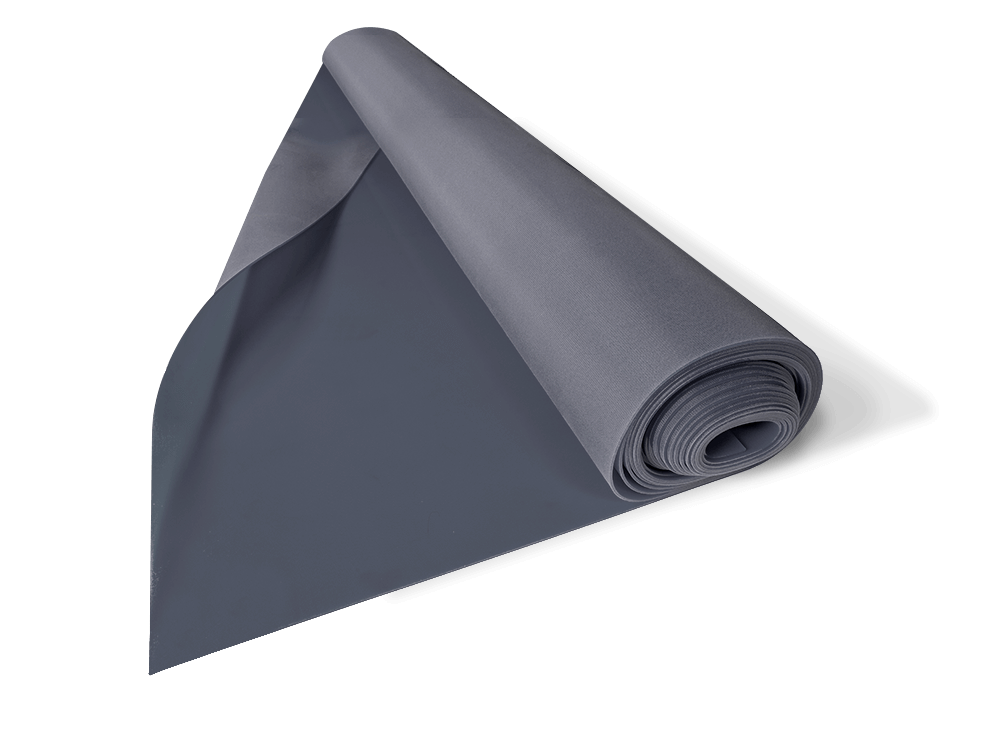

Natural rubber membrane

Both sides of the membrane are smooth and perfect for veneering with natural veneer. It is characterized by an extensibility of 600%, high chemical purity and no substances that may cause discoloration of the veneer. High density and homogeneity of the rubber mass guarantee long life and trouble-free operation of the membrane. Various diaphragm widths available. Forming and gluing with a membrane causes an even pressure on the entire plane of a flat or curved element, which positively affects the quality of the connection.

Area of aplication

- Membrane vacuum presses

- PVC foiling

- Wrapping elements with leather – dashboards, steering wheels, gear rods, etc.

- Bending of veneers / plywood / fibreboard – production of chairs, armchairs

- Veneering with natural veneer

- Bonding laminates

Technical data

| Thickness, mm: | 2.5 | 2.5 | 2.5 | 2.5 |

| Width, mm: | 1300 | 1500 | 1800 | 2000 |

| Temp. resistance °C: | 120 | 120 | 120 | 120 |

| Tensile strength, MPa: | 20 | 20 | 20 | 20 |

| Hardness, ShA: | 45 | 45 | 45 | 45 |

| Flexibility, %: | 600 | 600 | 600 | 600 |

| Tear strength, N / mm: | 60 | 60 | 60 | 60 |

| Colour: | Gray | Gray | Gray | Gray |

| Surface: | Smooth | Smooth | Smooth | Smooth |

Product photos

Natural rubber membranes

They are very resistant to mechanical damage, but have a lower temperature resistance than silicone rubbers. Therefore, natural rubber membranes are ideal for working with wood and wood-like materials in processes such as bending, veneering or gluing at temperatures up to 80⁰C. Rubber is an irreplaceable material in the production of coffins, door frame bands, custom-made furniture, orthopedic shoe inserts and other useful products. A very important parameter is also the hardness of the membrane, which is given in Shora’s units (ShA). The best parameters for the hardness of a rubber membrane that we have tested are 40-45 ShA. Be careful with sharp elements inserted under the membrane because damage to the rubber is associated with its replacement, as it will not be possible to create an appropriate negative pressure. In order to reduce the friction of the membrane, talc should be rubbed into it, which will lower the friction and extend its life.