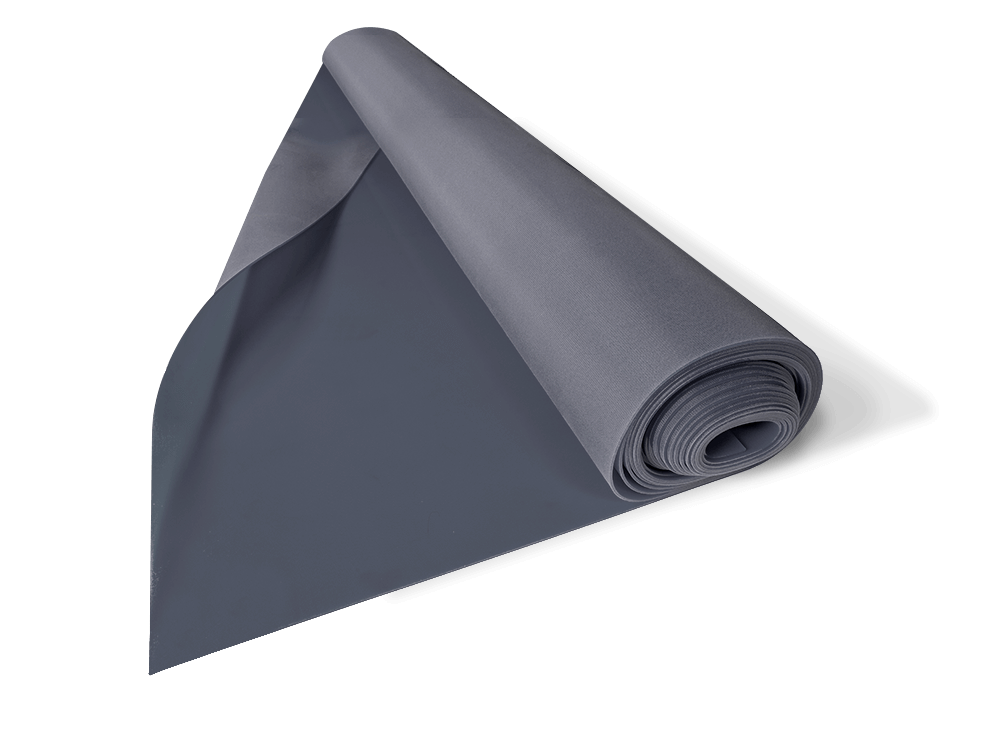

Membranes for vacuum presses

The membrane is a highly flexible material made mainly of silicone or rubber. It is used in vacuum presses as a flexible and strong material. The task of the diaphragm is to replace one part of the mold, because the rubber will adjust to the given surface, creating high pressure by vacuum. They are perfect for forming 2D and 3D curvilinear elements, such as: solid surface, natural veneer, wooden veneer, flexible plywood, etc. The silicone membrane is characterized by high temperature resistance, which can work at 220⁰C and 700% stretch. The natural rubber membrane is designed to work at temperatures up to 120⁰C and its elongation is 600%

Natural rubber membranes

Ideally suited for work with veneering, bending and gluing at temperatures up to + 90°C

Natural rubber membranes with increased parameters

It is characterized by high elongation at the level of 900% and increased strength parameters. Ideally suited for work with veneering, bending and gluing at temperatures up to +85°C

Silicone membranes

Ideally suited to work with solid surface, prepreg, and other materials formed at temperatures above + 90°C, even up to + 230°C

Glass laminating silicone membranes

They are ideal for laminating glass, a membrane of increased hardness used in the production process of safety glass