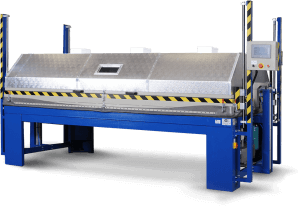

Vacuum pres VPS Special

Description

Vacuum press with pneumatically lifted membrane designed for 2D veneering, layered bending on a template as well as thermoplastic molding. Equipped with a heating system that allows you to shorten the gluing time and increase production efficiency. VPS vacuum presses are designed for small and large production plants.

Area of aplication

- Covering simple and shaped elements with natural veneer (doors, frames, chairs, tables, furniture, coffins)

- Veneering elements with HPL laminates in 2D format (kitchen worktops, window sills)

- Ironing of structural surfaces (stone veneer, decorative mats)

- Production of elements using the sandwich-sandwich method (columns, semicircles, flat surfaces)

- Wrapping the cockpit elements in the car with leather (dashboard, gear stick, etc.)

- Forming mineral-acrylic solidSurface plates, e.g. Corian, Staron, Hi-Macs, etc.

Molding of thermoplastic plastics

Construction

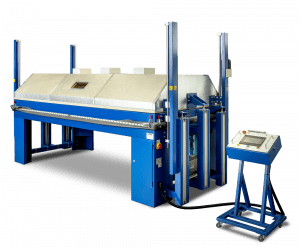

- Solid welded structure, powder coated

- Equipped with an electronic vacuum control system that allows the pump to operate automatically, and together with a buffer tank, it allows you to save electricity by turning off the pump after reaching the set vacuum value.

- Electronic heating system with a PID controller with an air mixer in the dome allows you to heat the press up to 80oC

- Built-in rubber membrane or optionally a silicone membrane

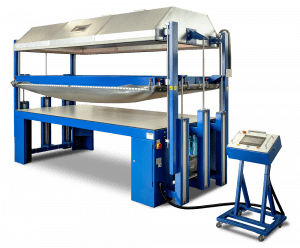

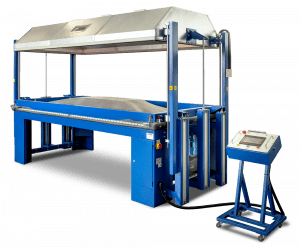

- Equipped with four pneumatic actuators for lifting the diaphragm with a heating dome

- Press table top made of HPL board, optional aluminum top

- Built-in vacuum pump -0,9 bar (9000) kg / m2

- Built-in buffer tank from 25 to 100 liters

- Upper heating dome made of aluminum, insulated with mineral wool – optional,

Technical data

| Hight closed /open | 2350mm |

| Lenght | 3550 mm |

| Tabel dimensions | 3000×1500 |

| Width | 1600mm |

| Weigt | 900 kg |

| Power supply | 400V |

| Vacuum pump power | 1,5 kw. |

| Vacuum pump performance | 40 m3 (Busch) |

| Pressure in the vacuum chamber | -0,90/-0,95 bar 9000 kg/m2 |

| Max working area of a flat element | 2750 x 1250mm |

| Height of the bent element at the width of 500mm | 500 mm |

| 3mm silicone membrane | 860% |

| Top heating operating temperature | 40-80 oC |

Configuration according to customer's wishes

Optionally, the machine can be configured according to the customer’s wishes, e.g .:

- aluminum worktop or version with a heated worktop

- increased maximum operating temperature of the dome

- installed system for quick cooling of thermoplastic elements through fans in the dome or a version of the machine without a heating dome for unconstrained cooling

- increased capacity of the vacuum pump

- controller for automatic operation

- an overview window of the pressing process with lighting installed in the dome

Convertible to comfort version:

The conversion to the VPS-300 SPECIAL / K model enables independent control of the lifting and lowering of the heating dome (especially useful for bending and forming very tall elements).