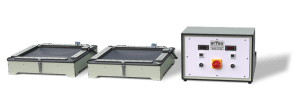

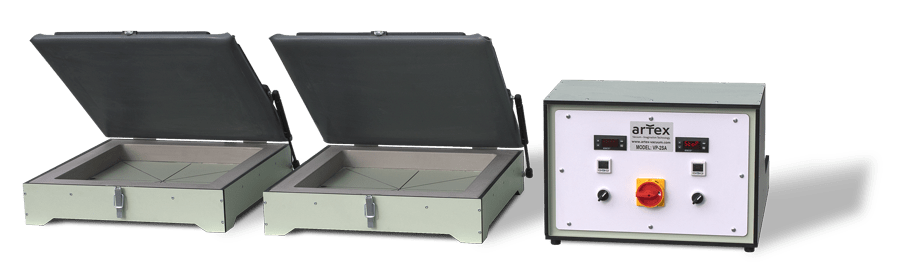

Vacuum press for orthopedic insoles

Application

Vacuum press for forming orthopedic insoles and production of leather shoe insoles.

Construction

- construction made of HPL boards

- electronic vacuum value control system

- vacuum pump timer

- rubber or silicone membrane

- automatic opening of the frame with the membrane after the end of the work cycle

Technical data

| Vacuum pump power, kW | 2 x 0,45 | ||

| Working voltage, V | 220-240 | ||

| Number of phases | 1 | ||

| Operating voltage frequency, HZ | 50 | ||

| Working current at full load, A. | 3,5 | ||

| Working vacuum, Bar | – 0,8 ÷ – 0,9 ± 0,05 | ||

Dimensions Control module 1. Lenght, 2. Width 3. Hight Membrane module 4. Lenght 5. Width 6. Hight |

610 mm 500 mm 360 mm

590 mm 550 mm 170 mm | ||

| Cover level | IP2X | ||

| Noise level, dB | 67 | ||

| Weight, kg | 80 | ||

Warranty

We provide a 1-year warranty on the device!

Product photos

Video

Remaining offer

Heating devices

The search for a new furniture design that will allow us to create a unique design is one of the basic tasks we set for ourselves today. Hot-air heating oven. Double-sided aluminum oven. Single-sided aluminum oven. Heating strips

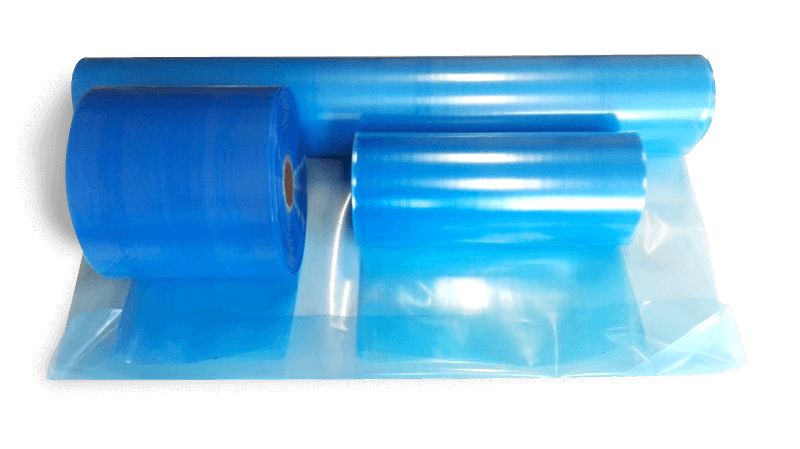

Membranes

The search for a new furniture design that will allow us to create a unique design is one of the basic tasks we set for ourselves today. Hot-air heating oven. Double-sided aluminum oven. Single-sided aluminum oven. Heating strips

Consumables

The search for a new furniture design that will allow us to create a unique design is one of the basic tasks we set for ourselves today. Hot-air heating oven. Double-sided aluminum oven. Single-sided aluminum oven. Heating strips