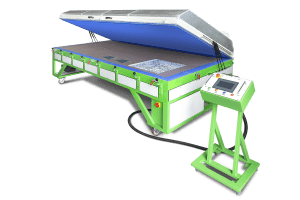

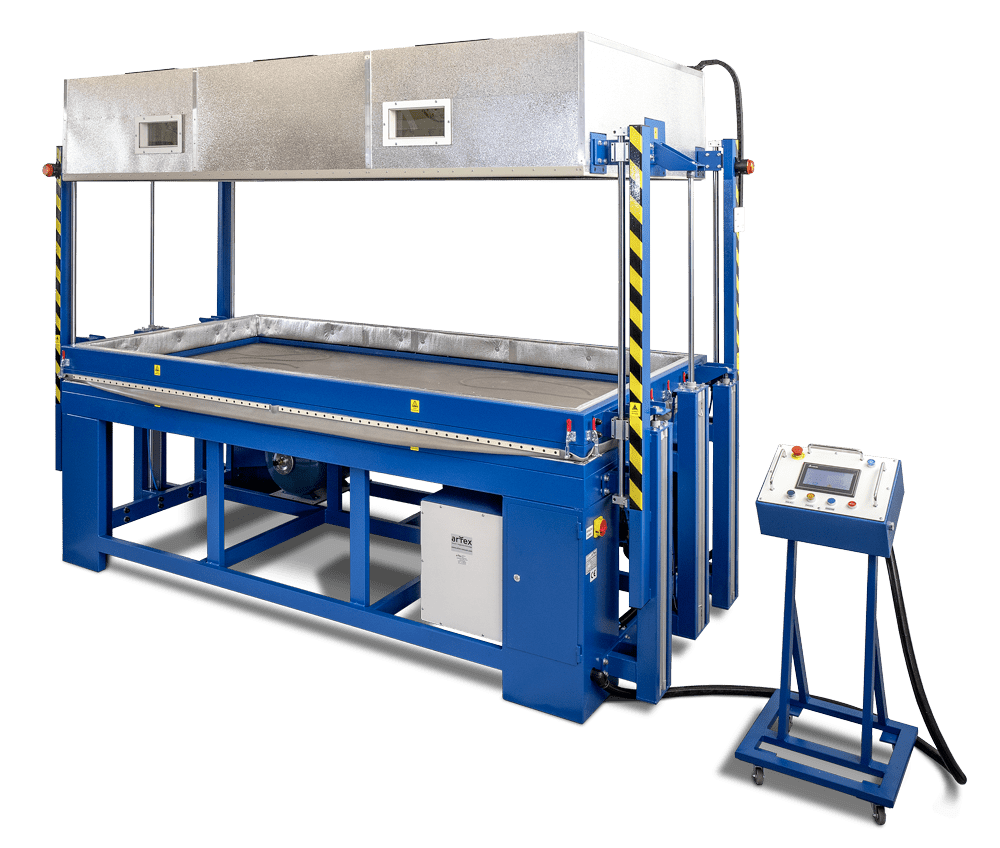

Glass lamination oven

Description

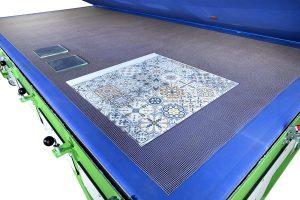

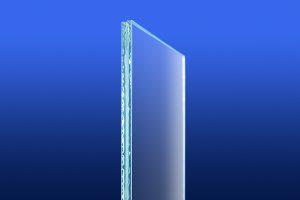

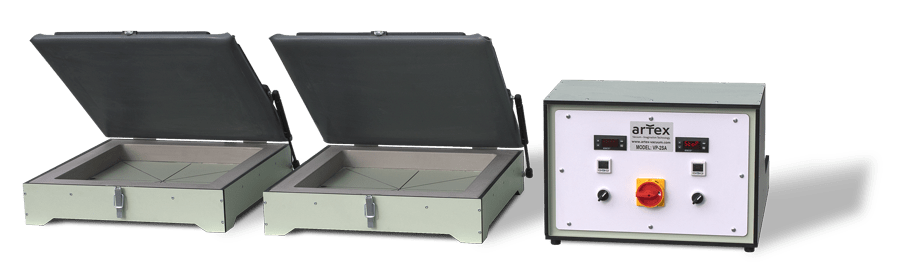

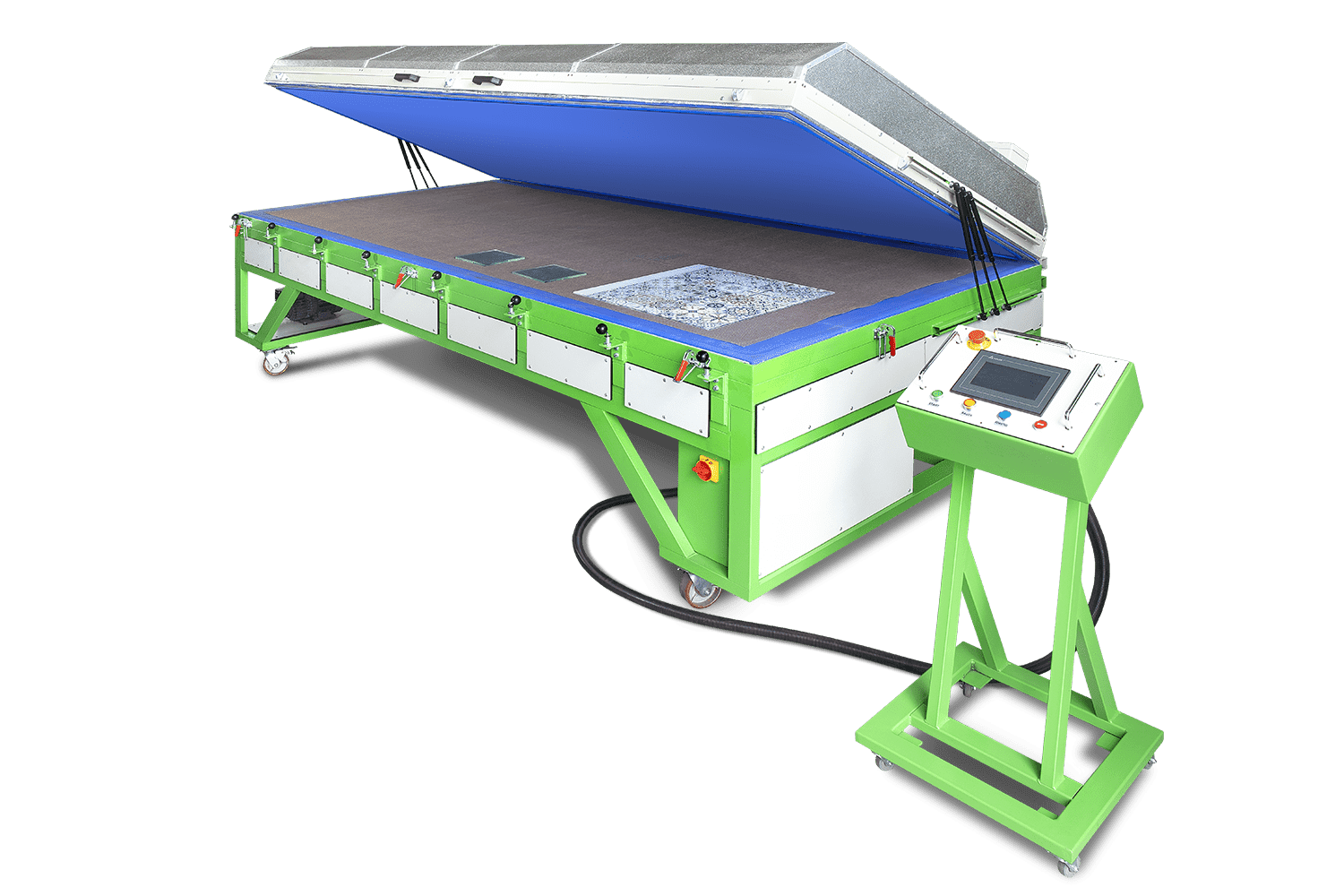

Glass lamination oven is used to create multi-layer safety glass and artistic glass with the use of appropriate foils or decorative papers. Heating with hot air ensures an even temperature distribution in the heating chamber. High vacuum and hermetic chamber ensure accurate connection of elements with each other. It is intended for small and large production plants. The press works in automatic mode.

Areas of application

- Production of safety glass VSG / ESG

- Production of VSG laminated glass

- Laminated art glass production

Construction

- Solid welded steel structure on wheels

- Heating system with electric resistance heaters and convection fans

- Pneumatic actuators for lifting the dome with the membrane

- Rubber rollers for easy glass loading

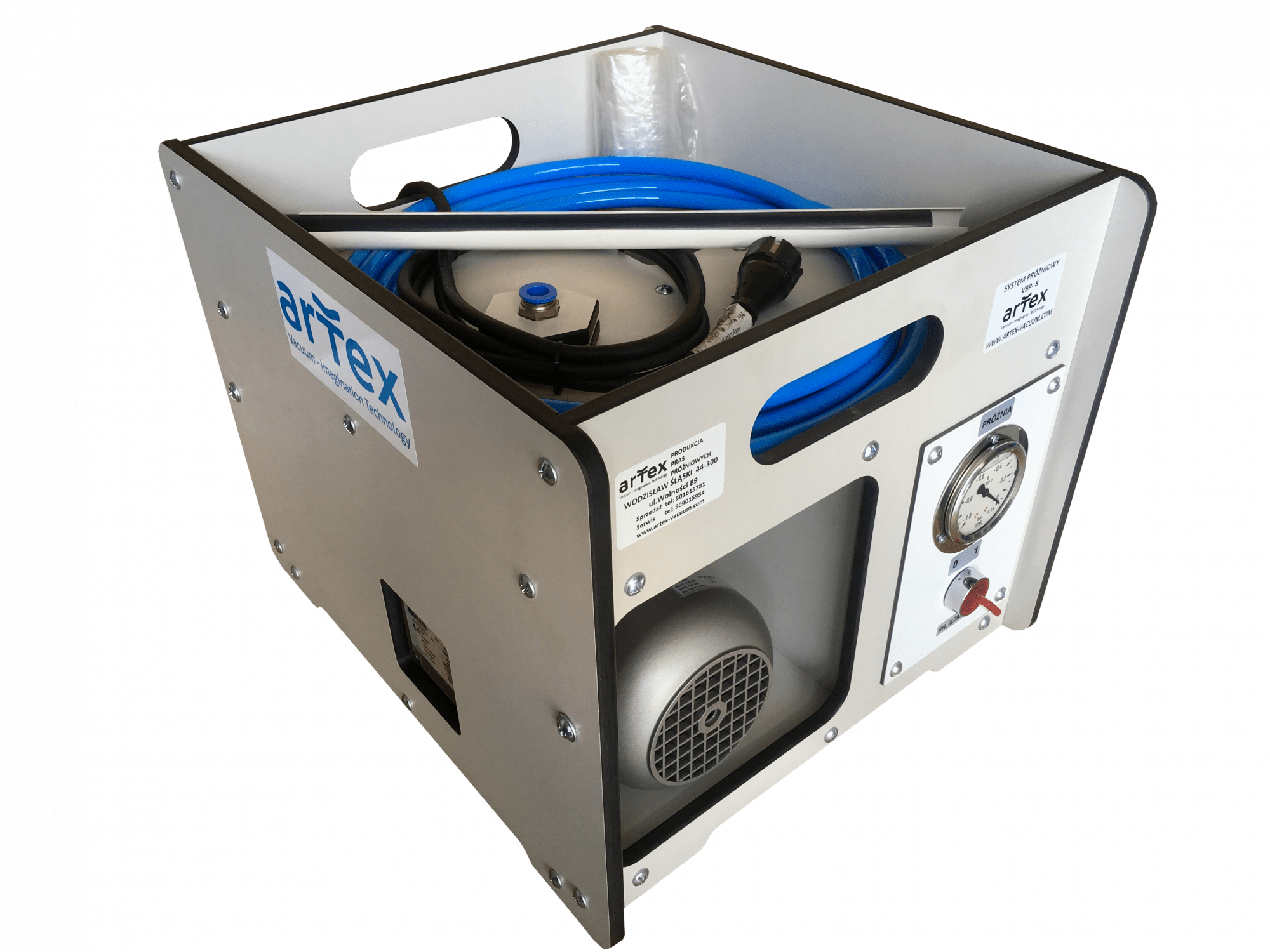

- Equipped with an electronic vacuum regulator

- Touch control panel

- Powder coated steel mesh table

- Built-in cooling with fans

- Built-in vacuum pump 20 m3 achieved vacuum value -0.95 bar (9500) kg / m2

- Built-in 100 liter buffer tank

- The upper heating dome is lined with stainless steel and insulated with mineral wool

Technical data

| Table working size, (length x width), mm: | 3300х1500 |

| Heating temperature, ° C max: | 200 |

| Heating power of heaters, kW: | 24 |

| Pump capacity, m3/ h: | 20 |

| Vacuum pump power, kW: | 0,7 |

| Operating vacuum, kg / m2 (bar): | – 0,95÷ -0,9 |

| Protection degree: | IP53 |

| Noise level, dB: | <70 |

| Voltage, V: | 3F 400V 50Hz |

| Dimensions, mm (length x width x hight): | 3550 x 1750 x 2630 |

| Weight, kg: | 900 |